The demand for high- performance electric motors is fleetly adding across diligence similar as automotive, home appliances, and artificial robotization. To meet these growing conditions, manufacturers are turning to automatic motor winding machine, which give perfection, effectiveness, and thickness in the coil winding process. These advanced machines exclude mortal error and ameliorate the overall quality of motor product, making them an essential part of ultramodern manufacturing.

The part of Automatic Motor Winding Machines

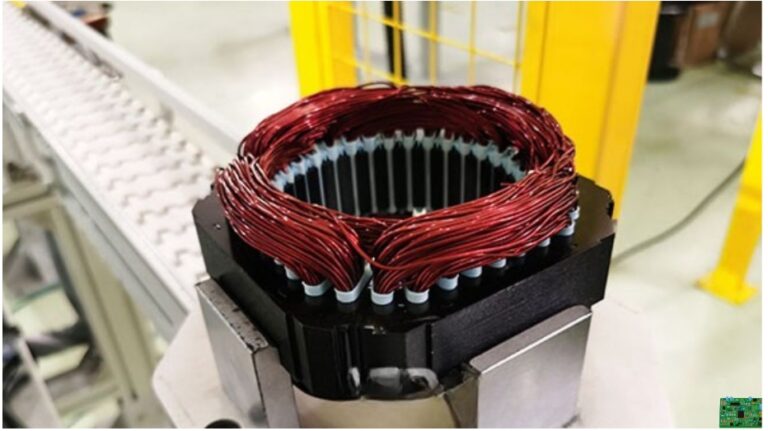

A automatic motor winding machine is designed to automate the coil winding process, icing invariant winding patterns and reducing homemade labor. This position of perfection is pivotal for maintaining motor effectiveness, reducing heat generation, and perfecting overall motor performance. The robotization also significantly increases product speed, allowing manufacturers to meet high- volume demands while maintaining harmonious quality.

In discrepancy to traditional winding styles, which bear professed labor and can be time- consuming, an electric motor winding equipment uses advanced programming and robotic robotization to complete the process efficiently. These machines come with customizable settings, allowing manufacturers to acclimate winding speed, line pressure, and coil configurations grounded on specific motor conditions.

Crucial Benefits of Electric Motor Winding Equipment

The use of electric motor winding equipment provides several advantages, including increased product effectiveness, bettered delicacy, and reduced material waste. These machines are equipped with ultramodern control systems that insure precise coil placement, reducing the threat of electrical losses and enhancing motor continuity.

also, automated winding machines reduce reliance on homemade labor, lowering product costs while maintaining high- quality affair. This makes them an ideal investment for businesses looking to ameliorate manufacturing effectiveness and product trustability.

Honest Machine Technology for Reliable Winding

One of the crucial factors in choosing the right automatic motor winding machine is trustability. Manufacturers seek honest machines — machines that deliver harmonious performance, bear minimum conservation, and give long- term functional effectiveness. A high- quality winding machine ensures that the line is wound with precise alignment and pressure, precluding blights and maximizing motor effectiveness.

By integrating smart robotization, electric motor winding equipment can cover the winding process in real- time, detecting any inconsistencies and making automatic adaptations. This not only improves product quality but also enhances overall product effectiveness, making it a favored choice for large- scale motor manufacturing.

Future of Automatic Motor Winding Machines

As diligence continue to introduce, the future of automatic motor winding machines will include AI- driven monitoring, prophetic conservation, and farther robotization. With increased demand for electric vehicles and energy-effective appliances, the need for high- perfection winding machines is more critical than ever.

By investing in advanced electric motor winding equipment, manufacturers can enhance productivity, reduce functional costs, and insure that their motors meet the loftiest performance norms. The elaboration of honest machines will continue to shape the future of motor product, driving effectiveness and invention across diligence.

FAQs

1. What’s an automatic motor winding machine?

An automatic motor winding machine is a device that automates the process of winding coils onto motor stators or rotors, icing perfection, effectiveness, and thickness in motor product.

2. How does electric motor winding equipment ameliorate product?

Electric motor winding equipment enhances product by reducing homemade labor, adding speed, icing invariant winding patterns, and minimizing material waste.

3. What makes an honest machine important in motor manufacturing?

An honest machine delivers dependable, high- quality winding performance with minimum crimes, icing that electric motors operate efficiently and have a longer lifetime.

4. Can an automatic motor winding machine handle different motor types?

Yes, utmost automatic motor winding machines come with customizable settings that allow them to wind coils for colorful motor sizes and designs.

Conclusion

The relinquishment of automatic motor winding machines has revolutionized the motor manufacturing assiduity by enhancing perfection, effectiveness, and trustability. These machines insure harmonious coil winding, reducing crimes and perfecting motor performance. With the advancement of electric motor winding equipment, manufacturers can streamline product, lower costs, and meet the growing demand for high- quality electric motors. The conception of honest machine — dependable, accurate, and effective winding results continues to shape the future of robotization in motor product. As diligence move toward smarter manufacturing, investing in advanced winding technology is essential for staying competitive and icing long- term success.